Getting the most out of your contracts

How relationship management can help you get the most out of your contracts

Just like oil helps you get the best out of your engine, relationship management can help you get the best out of your suppliers. Organisations across the private and public sectors in Australia are pulling all available levers to obtain the highest performance from their supply base. Our latest research report, Geared to High Performance, reveals that more than 70% of organisations deploy operational contract management, vendor management and strategic partner management to improve supply chain performance.

This is in stark contrast to those 30% of organisations who do not manage their contracts or do so for less than 10% of their contracts. Managing suppliers successfully is quite similar to the successful management of employees: the more (effort) you put in, the higher the return. Sitting tight and hoping for the best does not work. In the end, we are often buying professional services that are heavily dependent on the motivation of the supplier’s staff working together with our staff as one team. No wonder that leadership techniques work best: those clients who inspire, motivate, challenge and develop their suppliers achieve best performance.

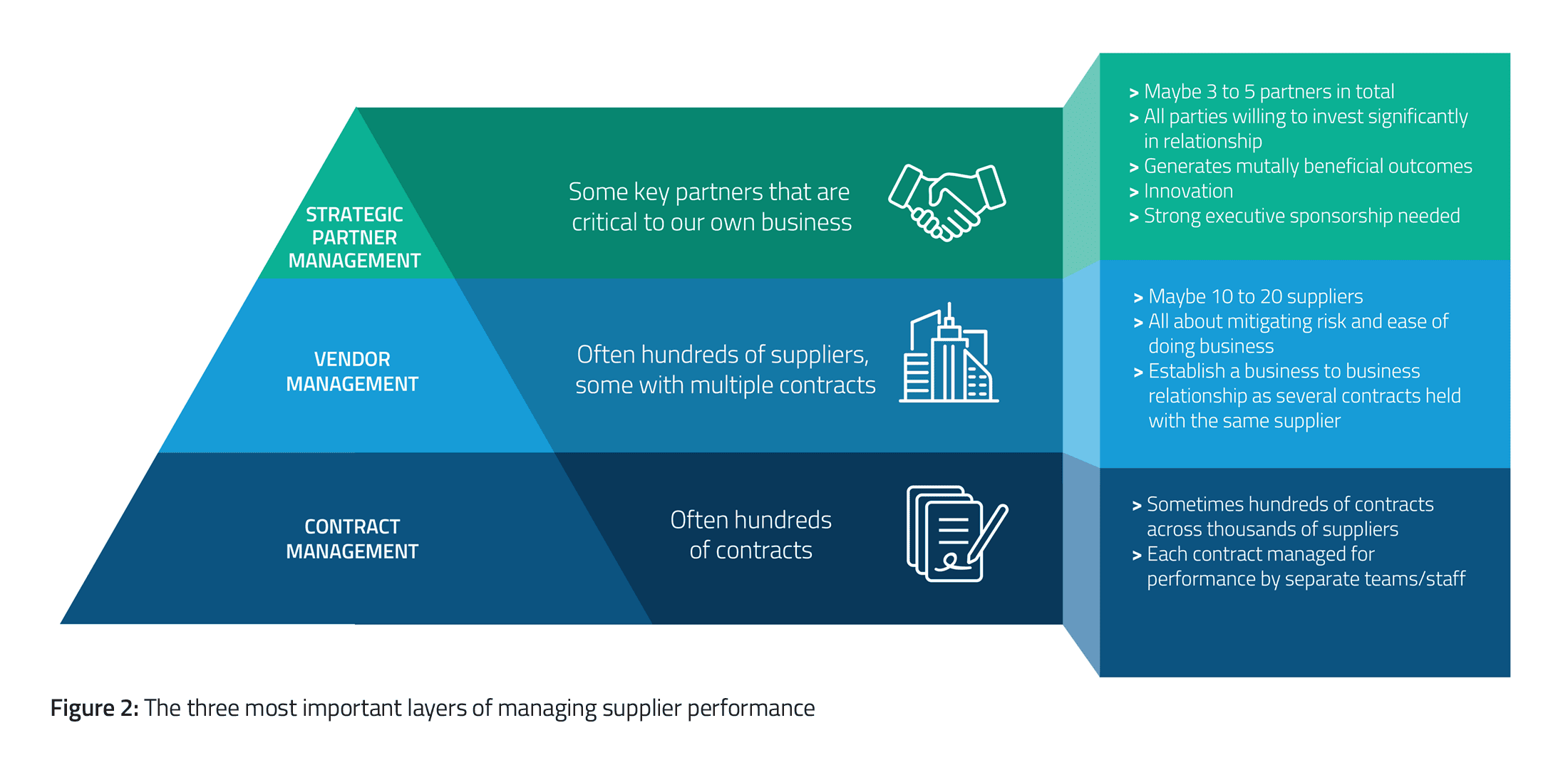

Three layers to managing a successful client/supplier relationship

At the operational level (refer Figure 2), there is Contract Management. This should be a proactive effort to get the most out of a specific contract for a specific service. It often includes contract administration and operational management activities, but ultimately the goal of contract management is to achieve best performance from the individual contract.

Above that is Vendor Management (refer Figure 2), which describes the effort to manage the business to business relationship, often with a vendor who has more than one contract with the client organisation. It is all about finding out how to improve processes, mitigation risks and overall being as easy to deal with each other as possible.

Strategic Partner Management (refer Figure 2) best operates at the executive level and with a small group of key suppliers. There is a large overlap in the strategic objectives of both organisations and thus a huge opportunity for joint growth and innovation.

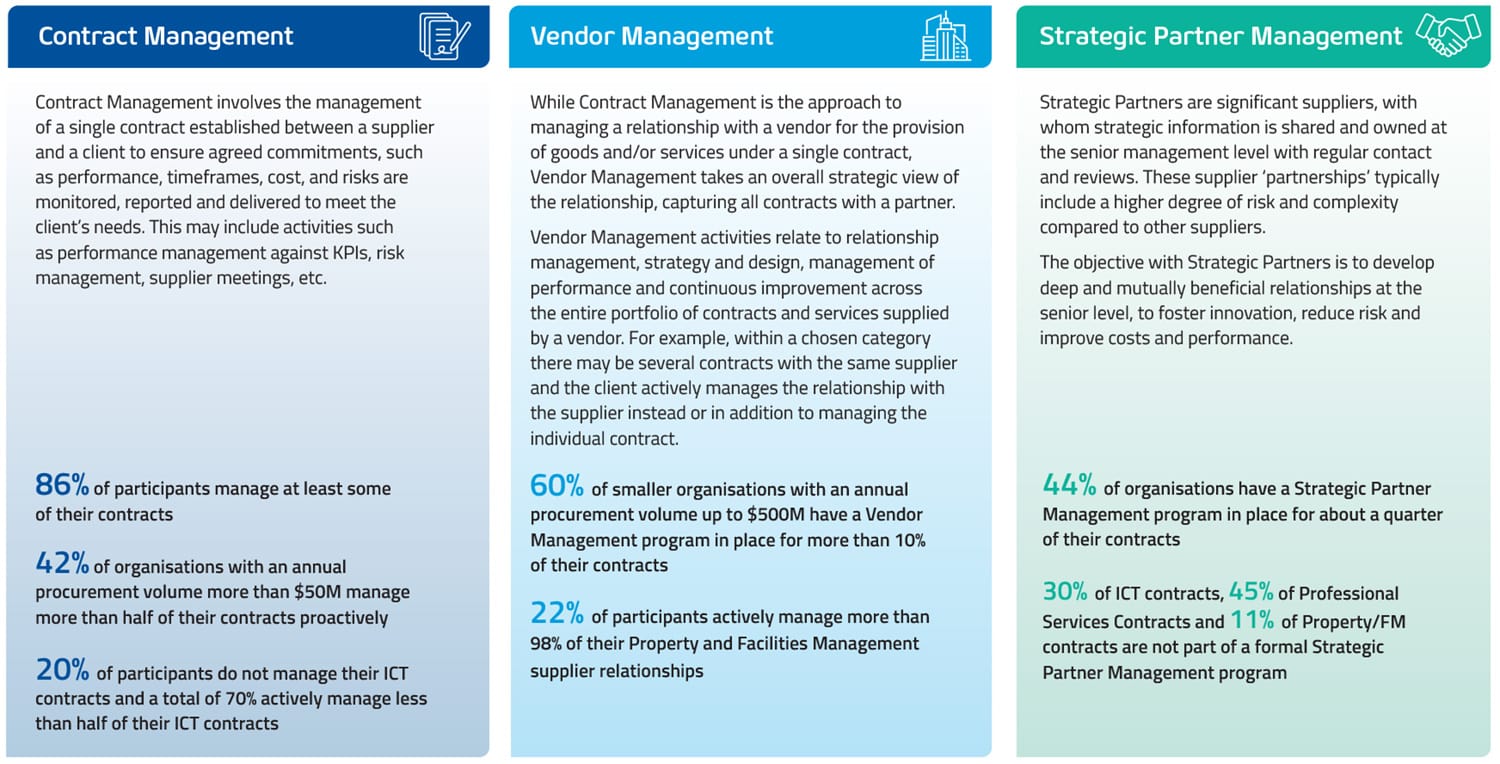

We have summarised in Figure 3 below how we define each of these layers and also how often we saw our research participants use these tools at their disposal to achieve best supplier performance.

Figure 3: Three layers for achieving high supplier performance

Do you get the most out of your contracts? Don’t know? Contact Stefan Gassner who would be happy to chat with you about your contracts.

What is operational contract management and why is it important?

Operational contract management is the day-to-day oversight of individual contracts to ensure deliverables are met, risks are mitigated, and value is realised. It’s critical because even well-negotiated contracts can underperform without active management.

How does vendor management differ from contract management?

While contract management focuses on individual contracts, vendor management looks at the relationship with a supplier across all contracts. It aims to improve processes, strengthen collaboration, and resolve issues holistically.

What is strategic partner management?

Strategic partner management sits at the executive or senior level, working with key suppliers to align long-term objectives, co-innovate, share risks, and drive mutual growth beyond transactional contracts.

At which stage of a contract should relationship management begin?

Relationship management should start during the procurement and contract negotiation phases and continue through the life of the contract. Early alignment of expectations, roles, and communication sets the foundation for success.

What are the main benefits of applying layered supplier management (contract, vendor, strategic)?

Layered management ensures you optimise value at all levels: contract performance, supplier efficiency and process improvement, and long-term strategic alignment and innovation.

How often should contract performance reviews be conducted?

Reviews should be periodic—monthly or quarterly for complex or high-value contracts, and at least annually for standard ones. The cadence depends on contract risk, complexity and importance to operations.

What metrics or KPIs should be tracked in contract management?

Some key metrics include service level adherence, cost variances, key deliverables met, defect or non-conformances, supplier responsiveness, and overall lifecycle costs.

How can you ensure the supplier is motivated and aligned with your goals?

You can share incentives, engage in joint planning, provide transparent feedback, build trust via regular communication, and treat the supplier as a partner rather than just a vendor.

What are common risks in procurement contracts and how can you mitigate them?

Common risks include scope creep, cost overruns, supplier non-performance, and contract ambiguity. Mitigate them via clear SOWs, performance clauses, change control processes, and governance structures.

When is it appropriate to renegotiate or reprocure rather than just manage a contract?

If market conditions change drastically, supplier underperforms persistently, or your requirements evolve significantly, renegotiation or even reprocurement may yield better value than continuing under an existing contract.

We are all about sharing our expertise to help you and your organisation be the best it can be.

We are all about sharing our expertise to help you and your organisation be the best it can be.